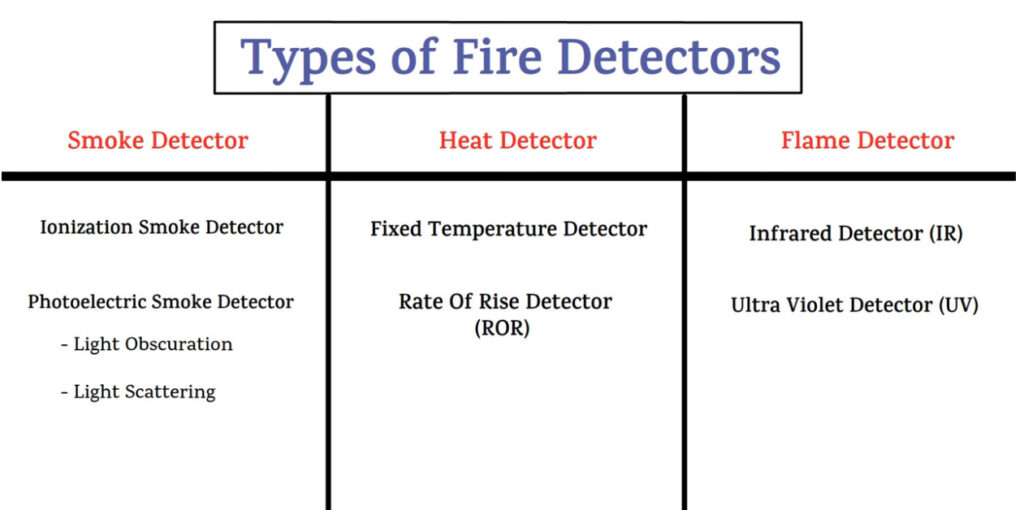

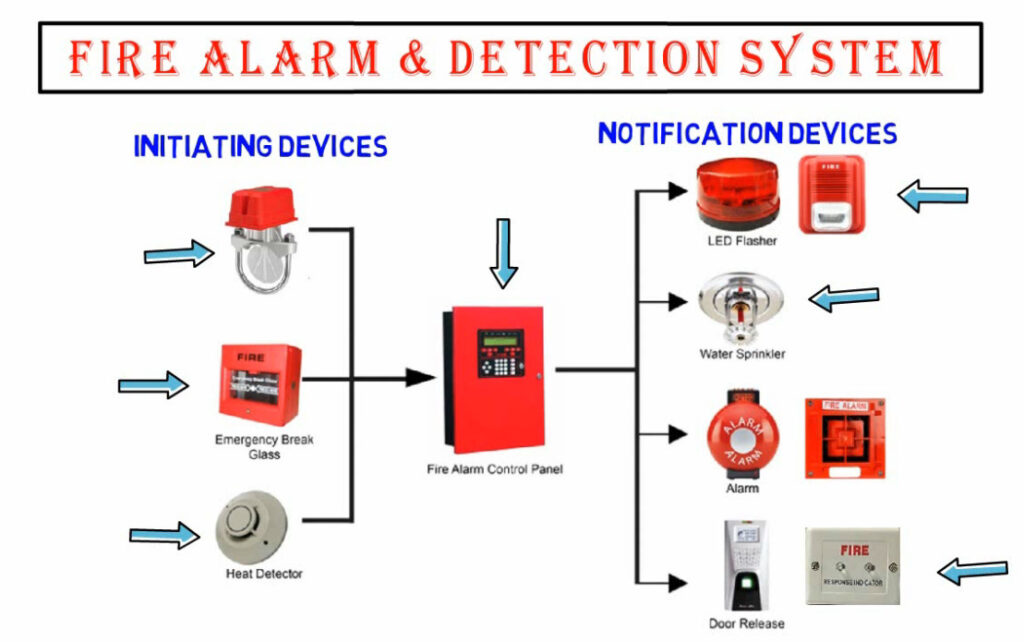

Fire alarm detectors are essential components of a fire alarm system, designed to detect the presence of a fire or smoke and trigger an alarm. There are several types of fire alarm detectors, each with unique detection methods suited to different environments and types of fires. Below are the primary types of fire alarm detectors:

1. Smoke Detectors

Smoke detectors are the most common fire detection devices. They detect the presence of smoke, which is a key indicator of a fire. There are two main types:

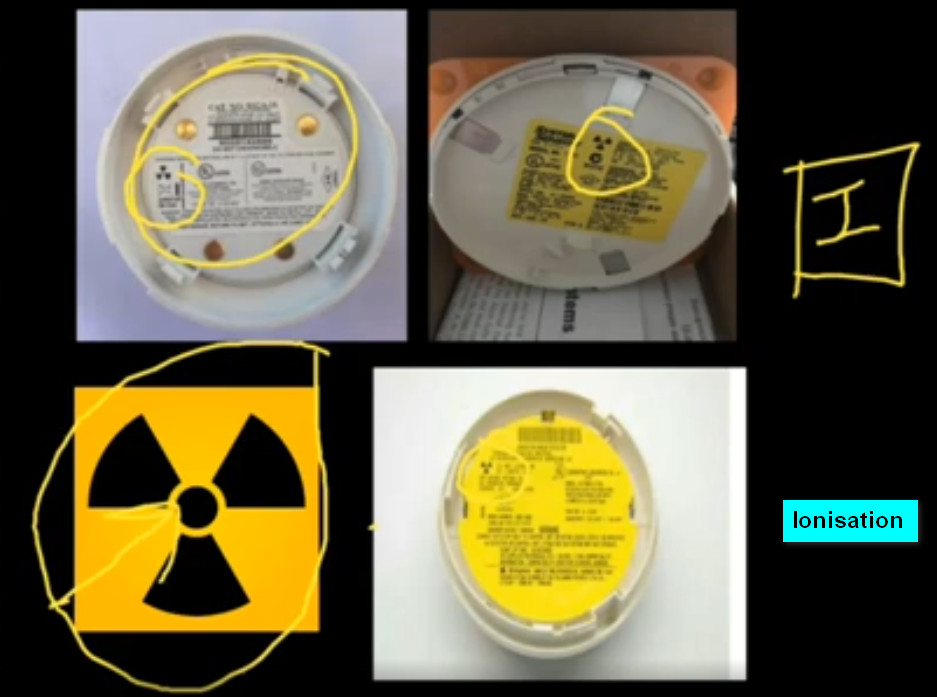

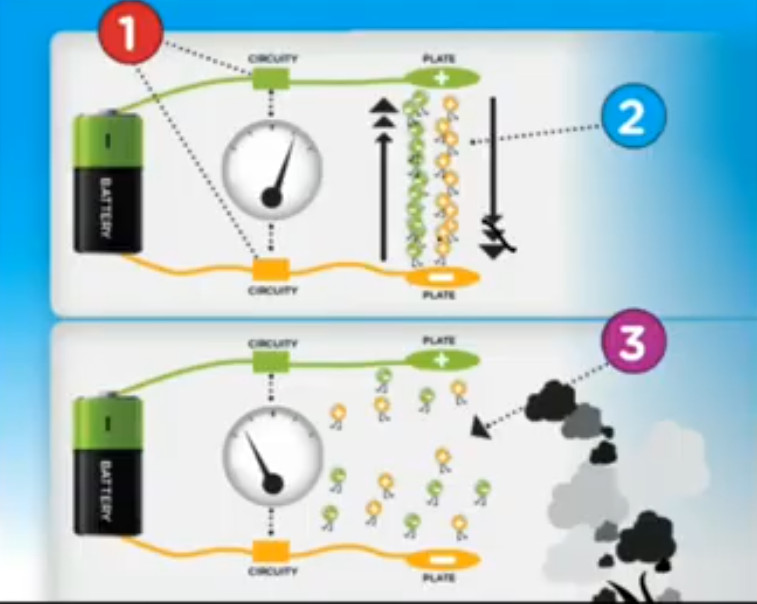

Ionization Smoke Detectors:

- How they work: These detectors use a small amount of radioactive material to ionize the air inside the detector. When smoke enters the sensing chamber, it disrupts the ionization process, triggering the alarm.

- Best for: Fast-flaming fires, such as those involving paper or flammable liquids.

- Advantages: They are highly sensitive to small smoke particles.

- Disadvantages: Less sensitive to smoldering fires and can be prone to false alarms due to cooking smoke or steam.

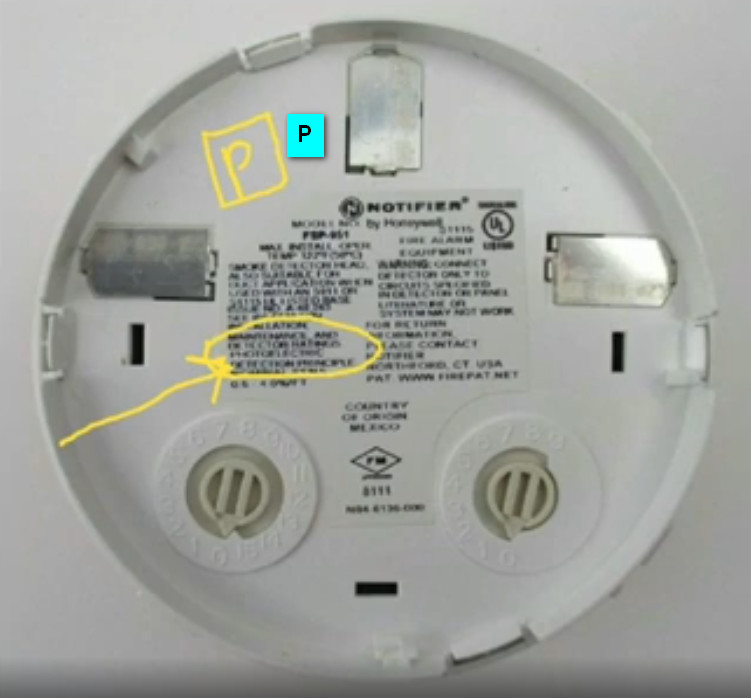

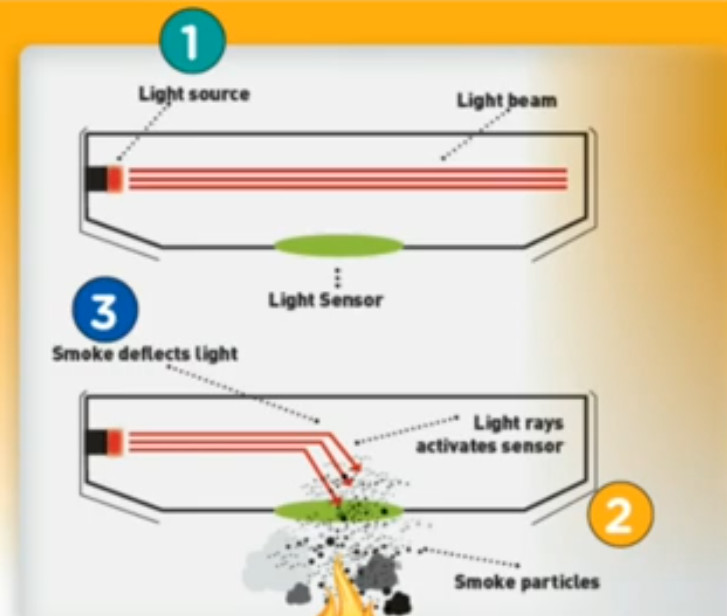

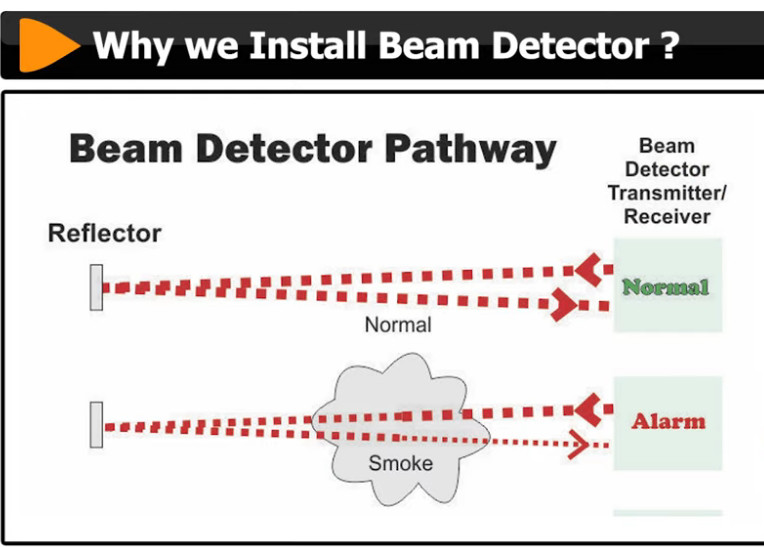

Photoelectric (Optical) Smoke Detectors:

- How they work: These detectors use a light source and a sensor. When smoke enters the chamber, it scatters the light beam, which is detected by the sensor and triggers the alarm.

- Best for: Smoldering fires, such as those involving upholstery, fabric, or furniture.

- Advantages: More effective at detecting smoldering fires and less prone to false alarms.

- Disadvantages: May be less sensitive to fast-flaming fires compared to ionization detectors.

2. Heat Detectors

Heat detectors respond to changes in temperature caused by a fire. They are typically used in environments where smoke detection is not ideal, such as kitchens, boiler rooms, or areas with high airflows.

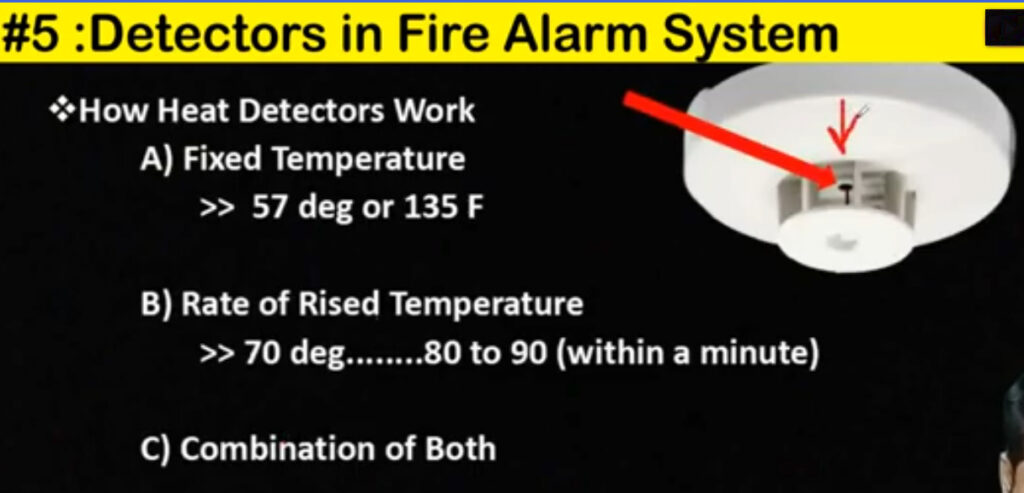

Fixed-Temperature Heat Detectors:

- How they work: These detectors are designed to activate when the temperature exceeds a preset threshold, usually between 135°F and 190°F (57°C and 88°C).

- Best for: Locations where smoke detectors may be prone to false alarms (e.g., kitchens or dusty environments).

- Advantages: Reliable in environments with high humidity, dust, or smoke.

- Disadvantages: They do not detect fires until the temperature rises significantly.

Rate-of-Rise Heat Detectors:

- How they work: These detectors activate when they detect a rapid increase in temperature (usually 15°F or more per minute).

- Best for: Areas where the fire’s intensity is growing quickly.

- Advantages: Can detect fires more quickly than fixed-temperature detectors in certain situations.

- Disadvantages: May not be suitable for environments where gradual temperature increases are common.

Combined Heat Detectors (Fixed and Rate-of-Rise):

- How they work: These detectors use both fixed temperature and rate-of-rise mechanisms for more reliable detection.

- Best for: Environments where both temperature rise and a steady temperature need to be monitored.

3. Flame Detectors

Flame detectors detect the presence of flames by sensing the radiation emitted by a fire. These detectors are highly sensitive and often used in industrial settings or areas with high fire risk.

- Types:

- Infrared (IR) Flame Detectors: Detect the infrared radiation emitted by a fire. They are suitable for detecting flames at a distance.

- Ultraviolet (UV) Flame Detectors: Detect ultraviolet radiation emitted by flames. These are often used in areas with bright ambient light, such as industrial environments.

- Combined IR and UV Detectors: Some detectors combine both infrared and ultraviolet technologies for greater sensitivity and reliability.

- Best for: Industrial environments, hazardous locations, or areas where flame detection is critical (e.g., chemical plants, refineries).

- Advantages: They are fast to detect flames and can be used in open spaces.

- Disadvantages: They are less effective in detecting smoldering fires, and UV detectors can be affected by sunlight or artificial lighting.

4. Carbon Monoxide Detectors

Carbon monoxide (CO) detectors are used to detect the presence of CO, a colorless, odorless gas produced during incomplete combustion. These detectors can be part of a fire alarm system or a separate device for detecting gas leaks.

- How they work: CO detectors measure the concentration of carbon monoxide in the air. When the levels exceed a certain threshold, the alarm is triggered.

- Best for: Environments where combustion occurs (e.g., kitchens, garages, or industrial areas).

- Advantages: Can detect dangerous CO levels, which may indicate a fire or malfunction in heating systems.

- Disadvantages: Not specifically designed for fire detection, and CO may not always indicate the presence of a fire.

5. Multi-Sensor Detectors

Multi-sensor detectors combine multiple detection technologies (e.g., smoke, heat, and carbon monoxide sensors) into a single device. These detectors provide more accurate and reliable detection by using multiple detection methods to minimize false alarms and enhance performance.

- How they work: These detectors use sensors that detect various elements, such as smoke, heat, and CO, in one unit. The system will only activate the alarm if multiple sensors detect a fire.

- Best for: Environments with varying conditions (e.g., kitchens, warehouses, or areas with fluctuating temperatures or humidity).

- Advantages: More reliable and less prone to false alarms.

- Disadvantages: More expensive than single-sensor detectors.

6. Gas Detectors

These detectors monitor the air for the presence of various gases, such as methane, propane, or other flammable gases. They are used to detect gas leaks, which may lead to fires or explosions.

- How they work: Gas detectors use sensors to detect the concentration of specific gases. When the concentration exceeds a preset level, the alarm is triggered.

- Best for: Industrial environments, commercial kitchens, or areas where flammable gases are used.

- Advantages: Can prevent fires caused by gas leaks before they escalate.

- Disadvantages: Not always part of a typical fire alarm system but can be integrated into more comprehensive safety systems.

Summary of Common Fire Alarm Detectors:

| Type of Detector | How it Works | Best For | Advantages | Disadvantages |

|---|---|---|---|---|

| Ionization Smoke Detector | Detects small smoke particles using ionization | Fast-flaming fires | Sensitive to fast-burning fires | Prone to false alarms from cooking or steam |

| Photoelectric Smoke Detector | Detects scattered light from smoke particles | Smoldering fires | Effective for smoldering fires, fewer false alarms | Less sensitive to fast-flaming fires |

| Fixed-Temperature Heat Detector | Activates when temperature exceeds a preset value | Areas prone to temperature changes | Reliable in dusty or humid environments | Doesn’t detect fire until significant temperature rise |

| Rate-of-Rise Heat Detector | Activates with rapid temperature increase | Quick-growing fires | Faster detection in high-heat environments | May not detect gradual temperature changes |

| Flame Detector | Detects radiation from flames (IR or UV) | Industrial settings, chemical plants, refineries | Quick flame detection, effective in open spaces | Not effective for smoldering fires |

| Carbon Monoxide Detector | Detects carbon monoxide gas | Areas with combustion (e.g., kitchens, garages) | Detects dangerous CO levels, indicates incomplete combustion | Not specifically for fire detection |

| Multi-Sensor Detectors | Combines smoke, heat, and/or CO detection | Variable environments | Reduces false alarms, more reliable | More expensive than single-sensor detectors |

| Gas Detectors | Detects specific flammable or toxic gases | Industrial areas or kitchens using flammable gases | Prevents explosions or fire from gas leaks | Not typically part of standard fire alarm systems |

Each type of detector is designed to work in specific environments and for specific types of fires. In many cases, fire alarm systems may combine multiple types of detectors to ensure reliable and early detection of different fire scenarios.