- 8777701917

- info@saikatinfotech.com

- Basirhat W.B

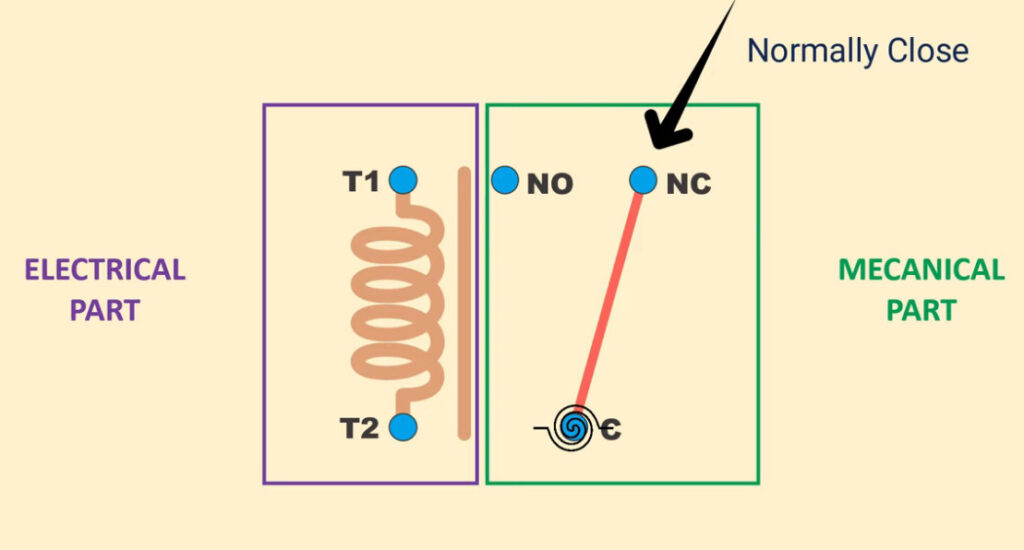

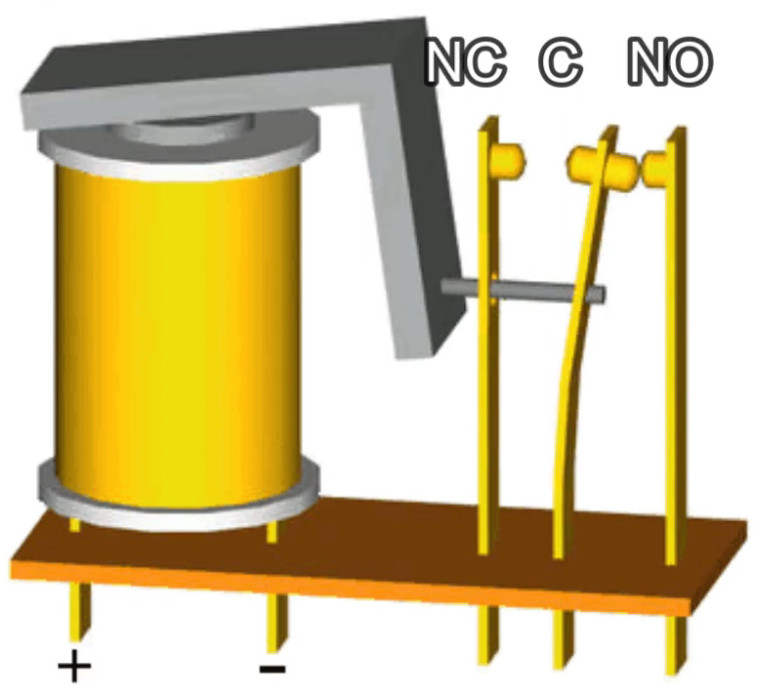

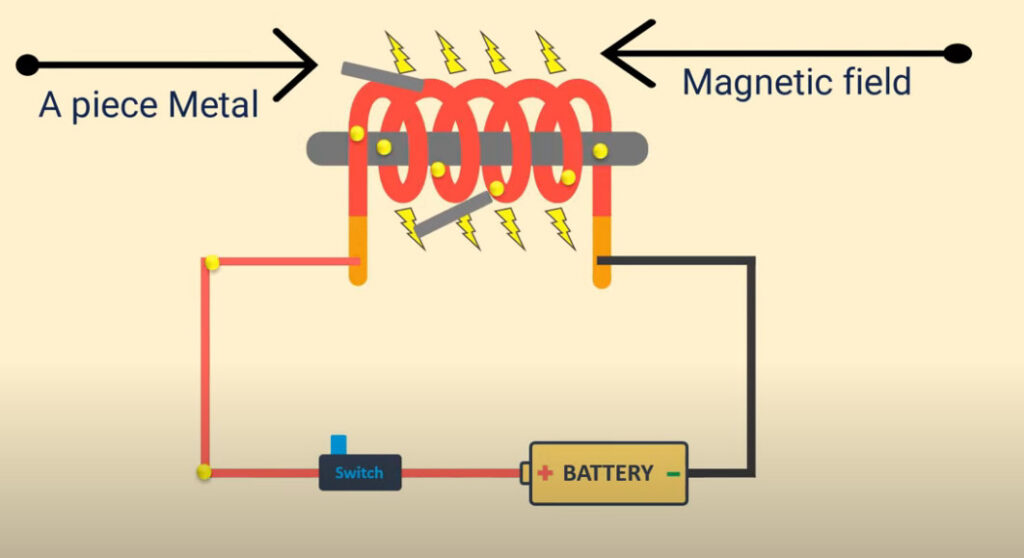

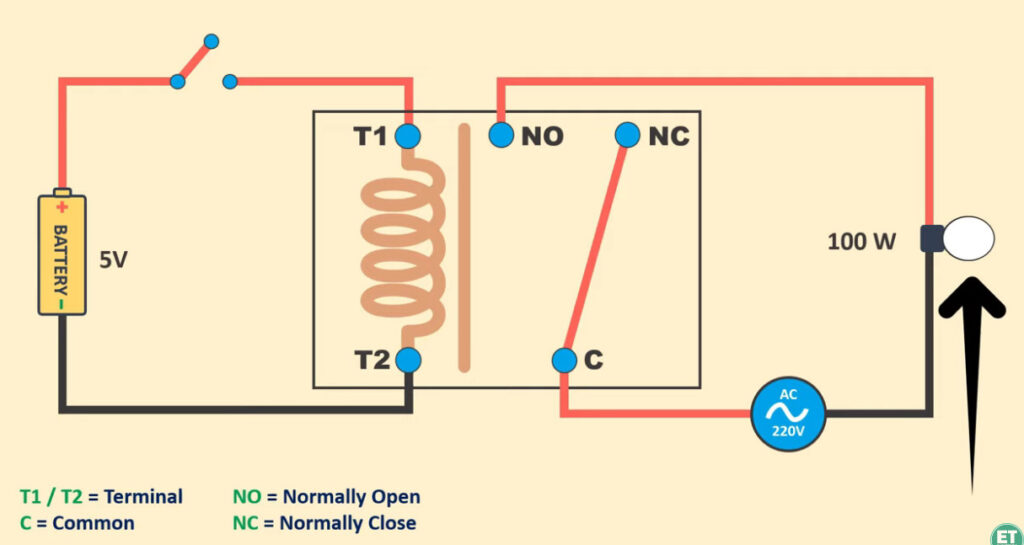

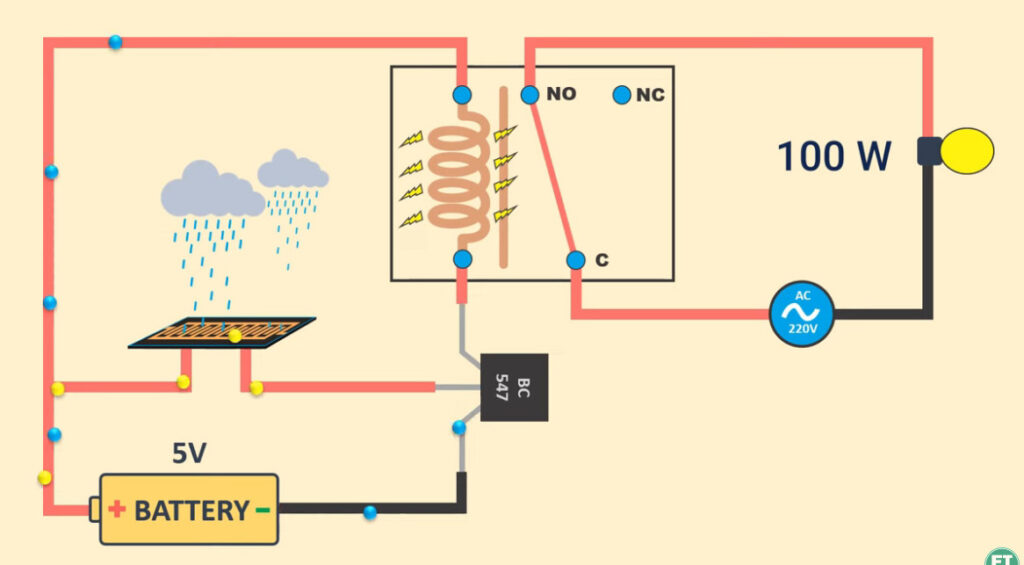

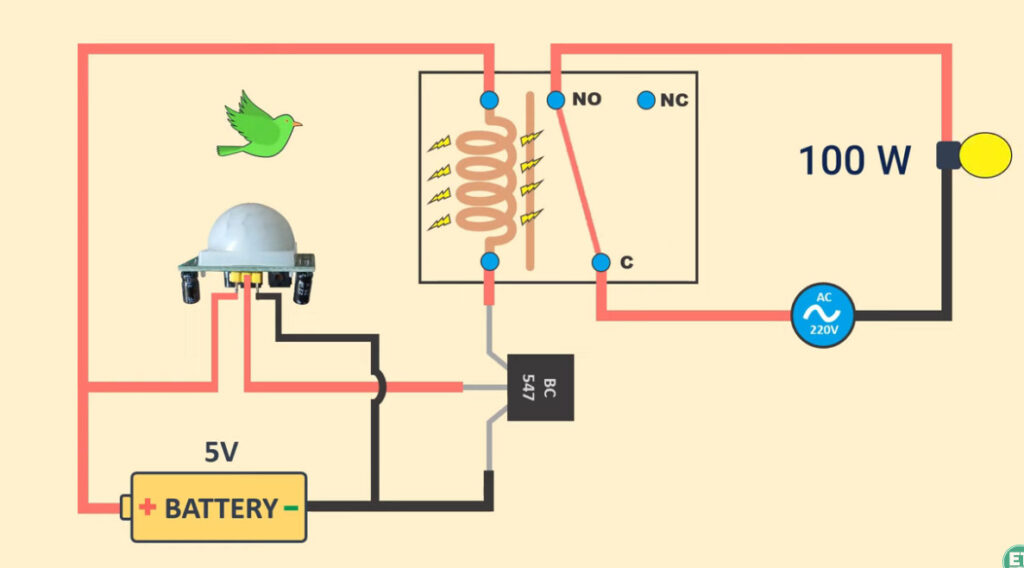

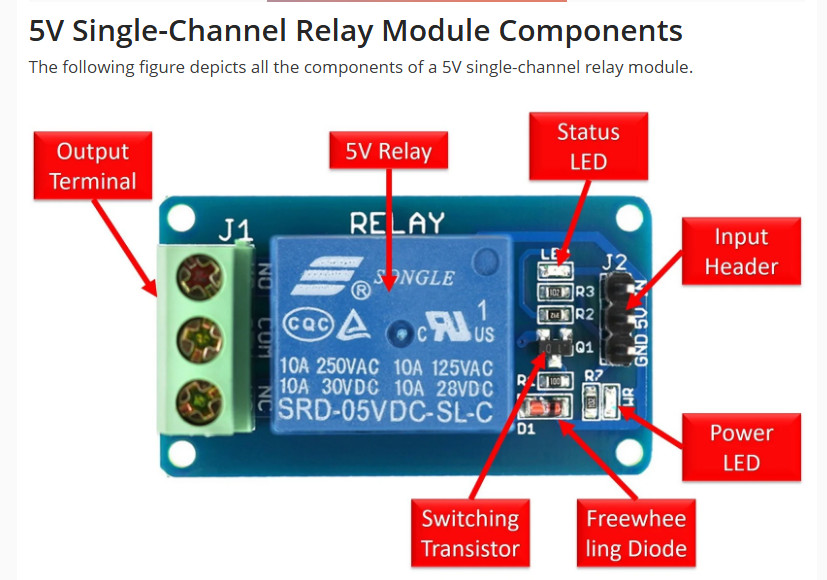

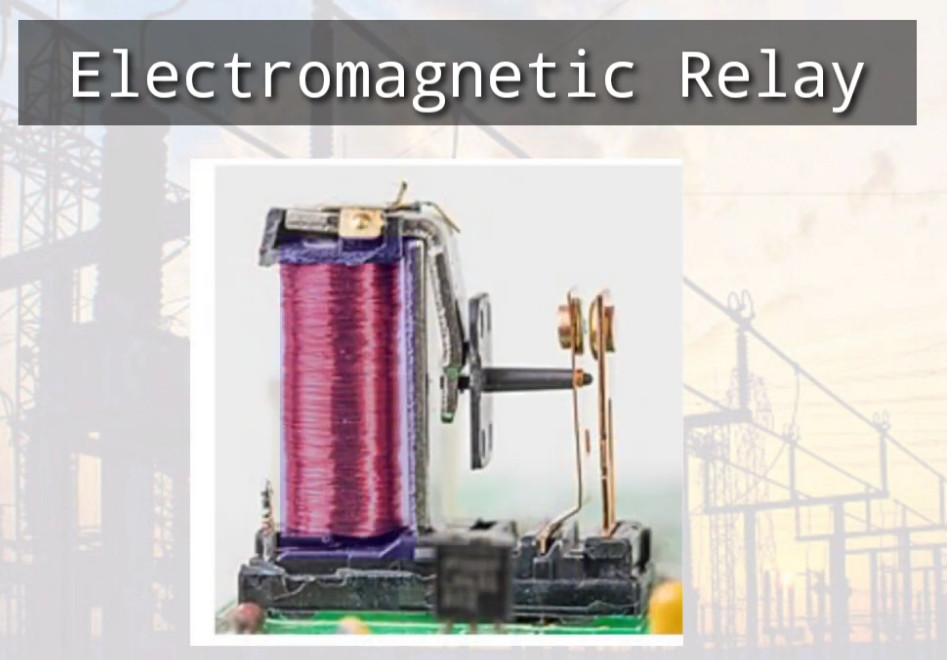

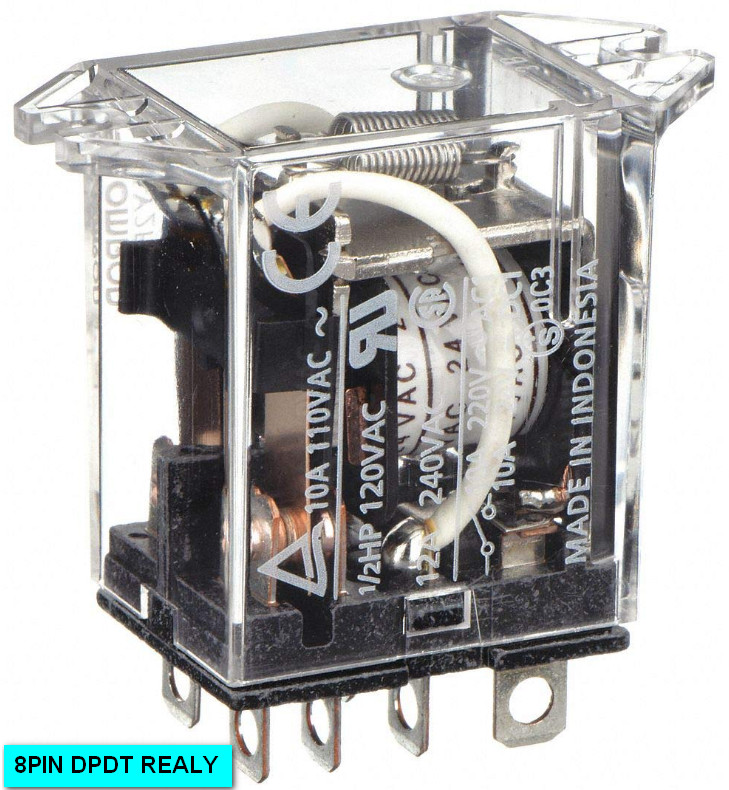

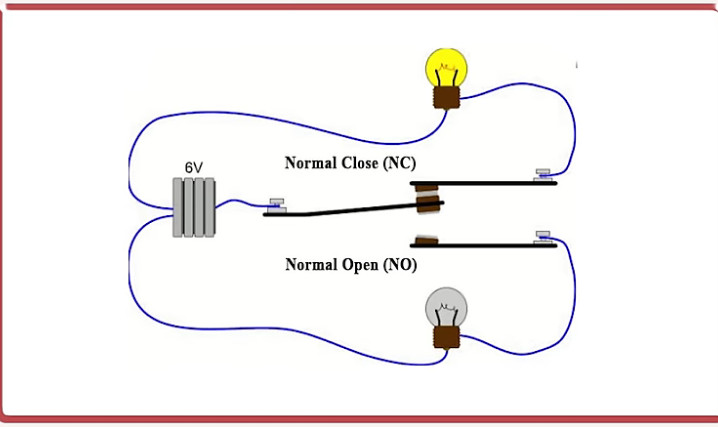

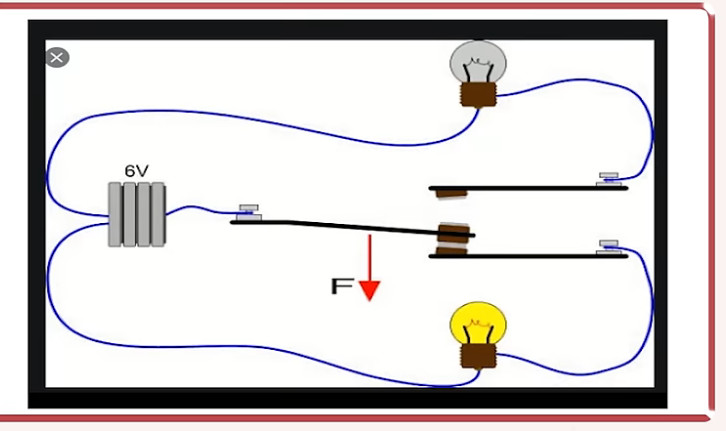

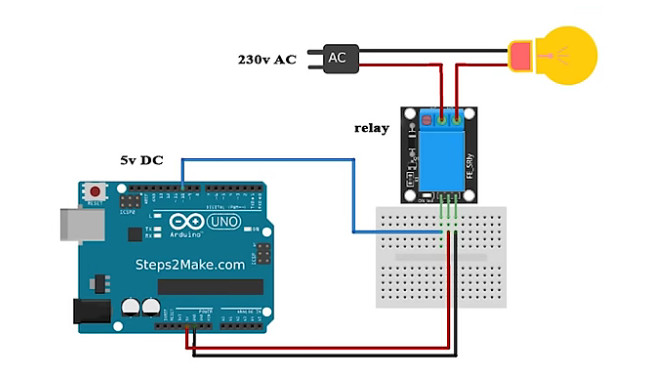

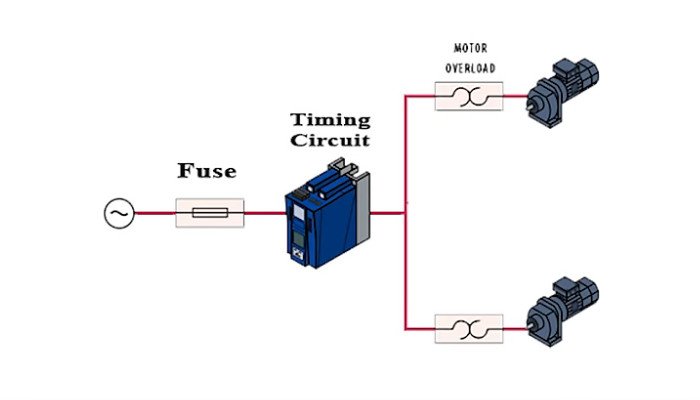

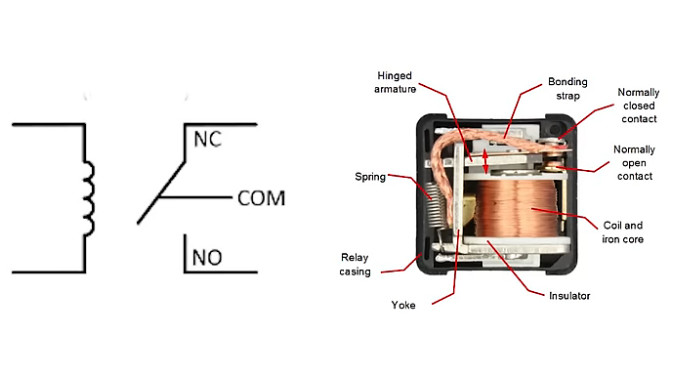

A relay is an electrically operated switch that allows you to control a high-power or high-voltage circuit with a low-power signal. It consists of an electromagnet, a spring-loaded switch, and a set of contacts. When an electric current passes through the coil (electromagnet) of the relay, it creates a magnetic field that pulls a set of contacts together or separates them, thus controlling the flow of current in another circuit.

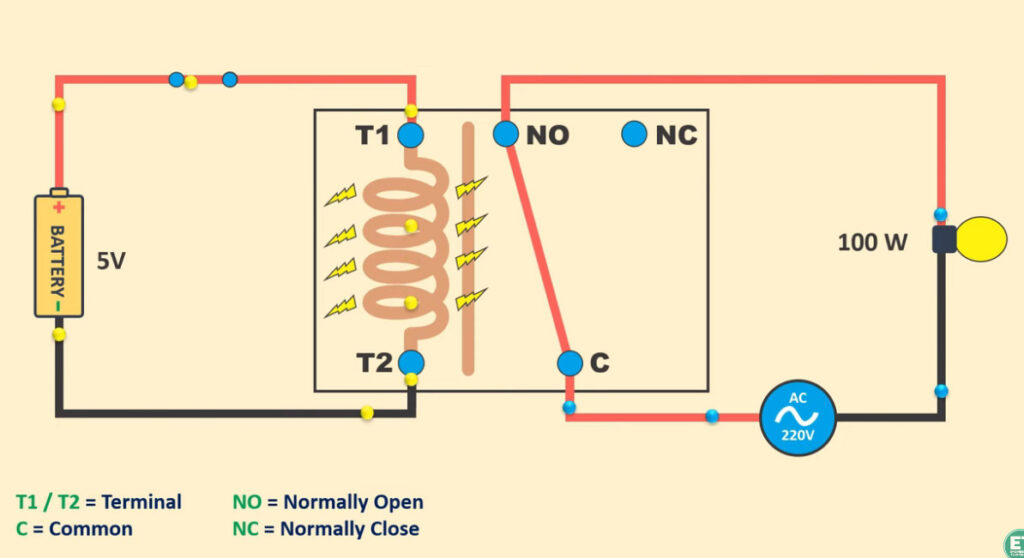

Electromagnet Activation:

Switching Mechanism:

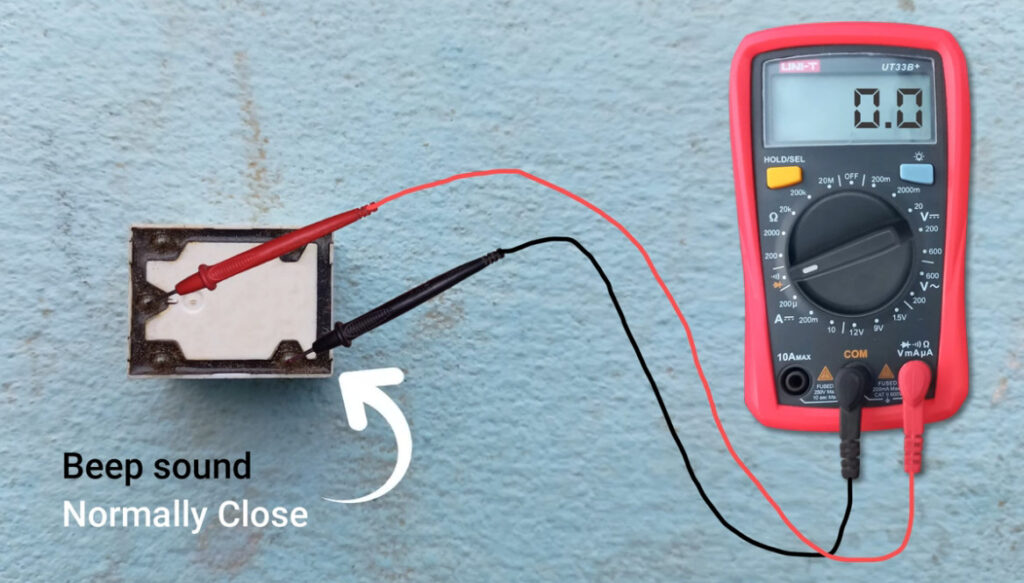

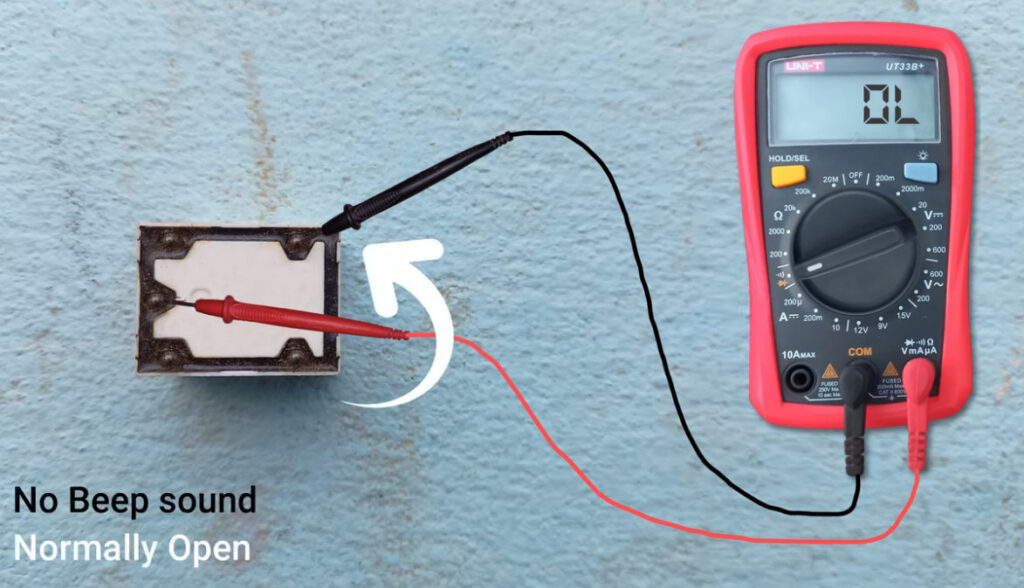

Contacts:

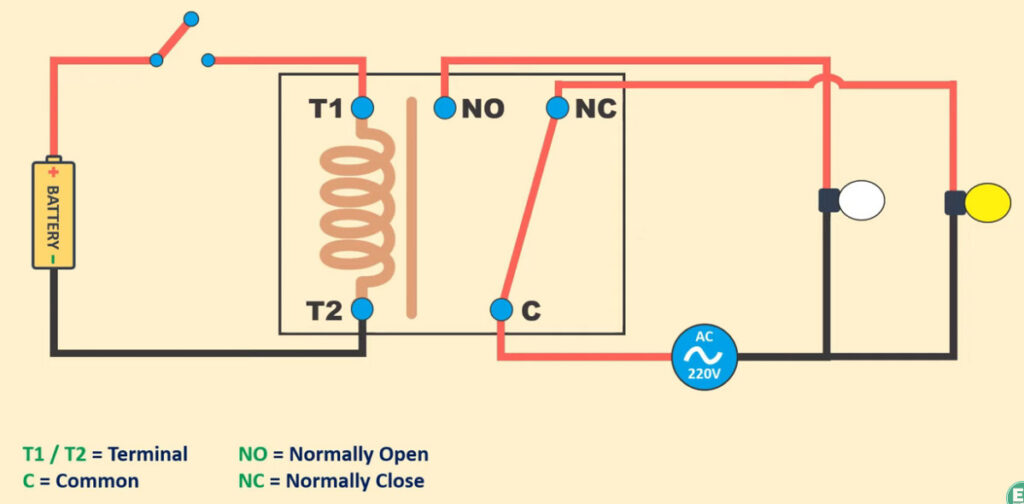

Returning to Default State:

In summary, a relay allows a small electrical signal to control a much larger electrical load, providing a safe, efficient way to switch circuits on and off.

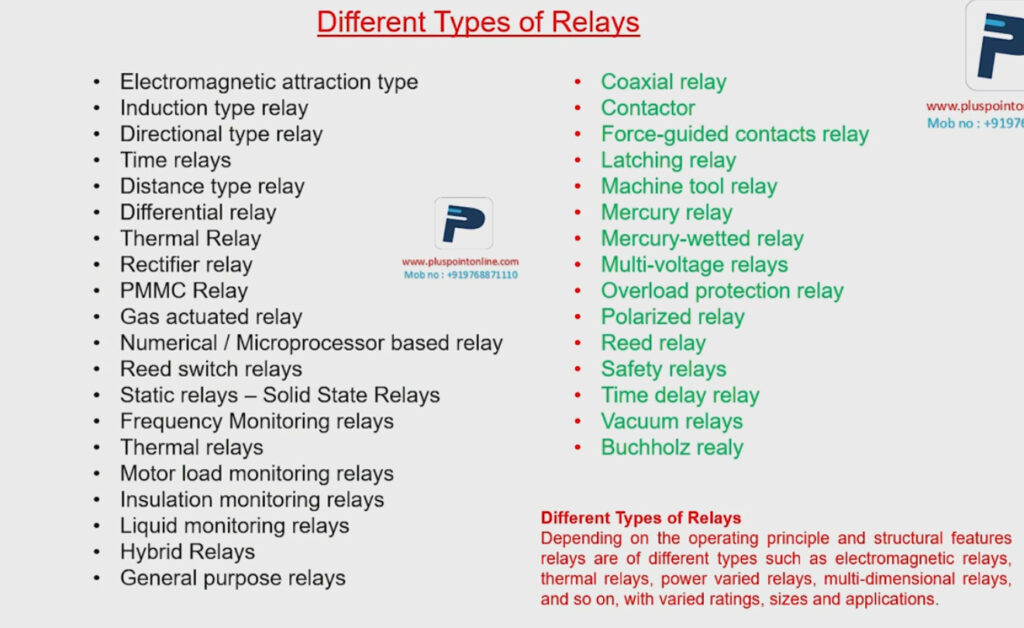

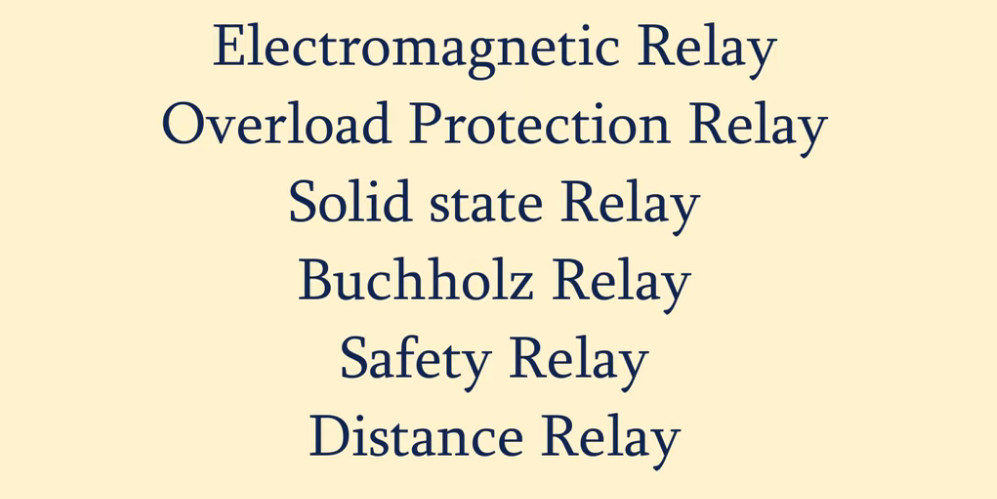

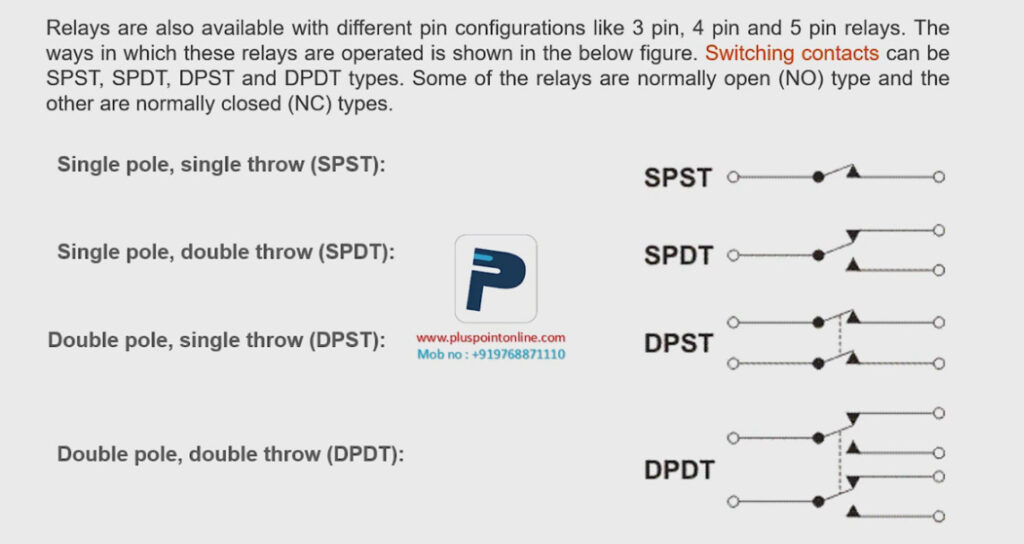

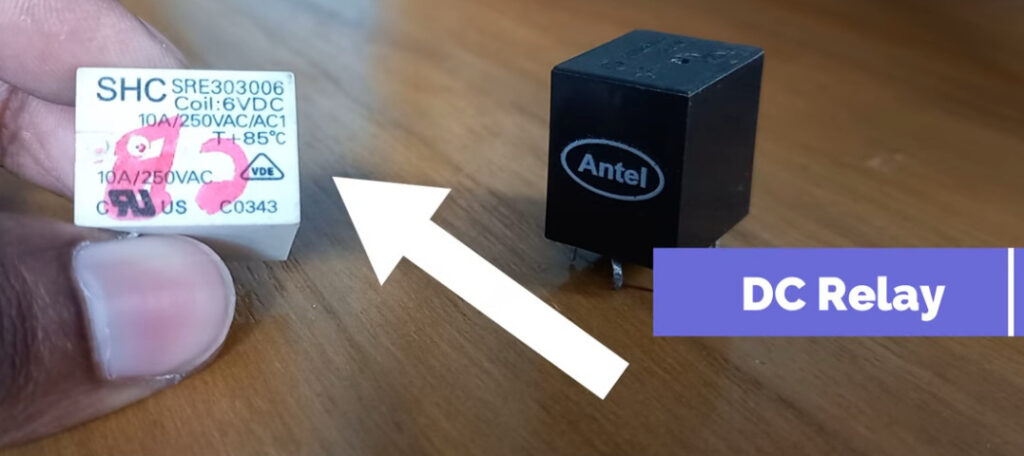

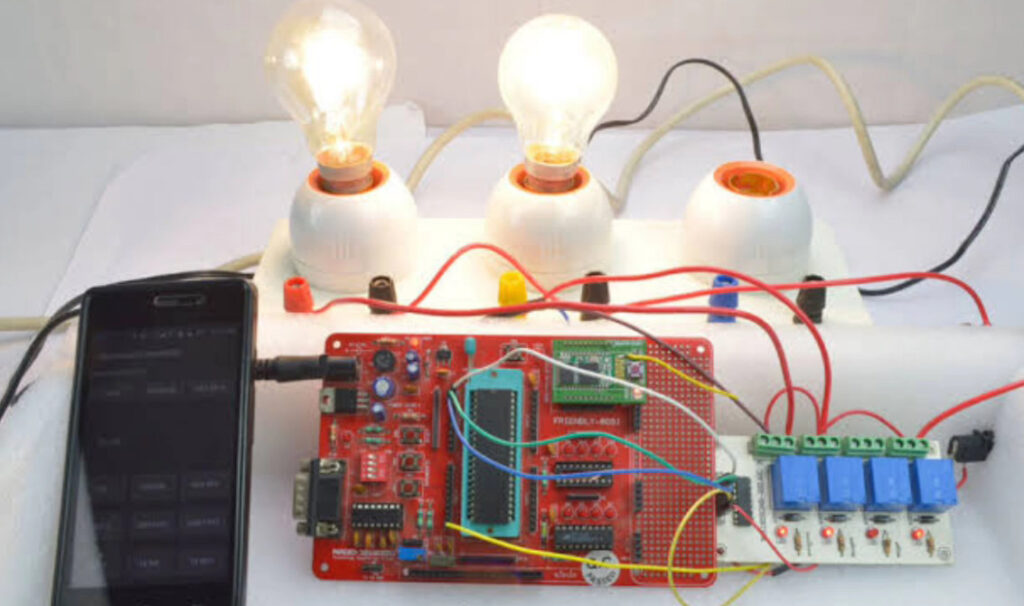

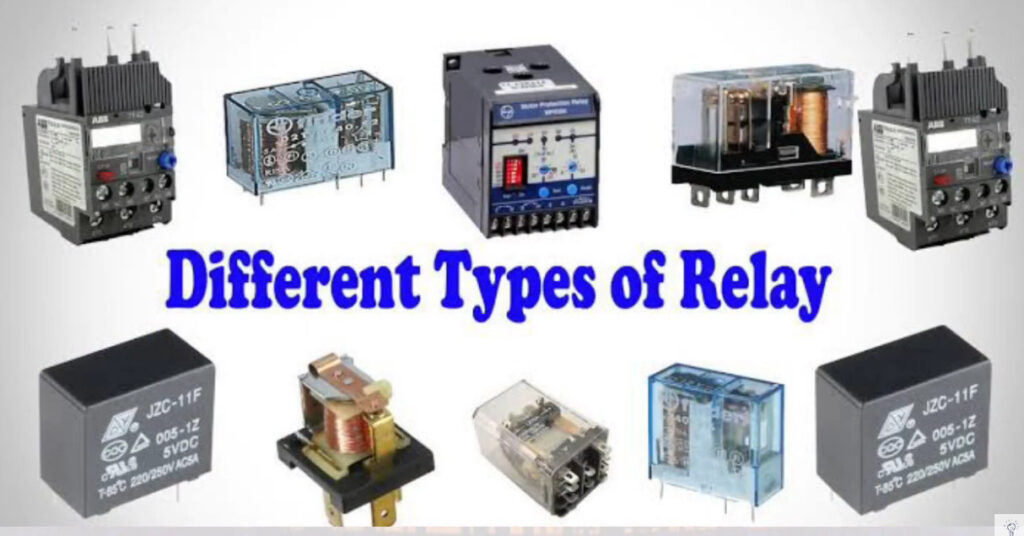

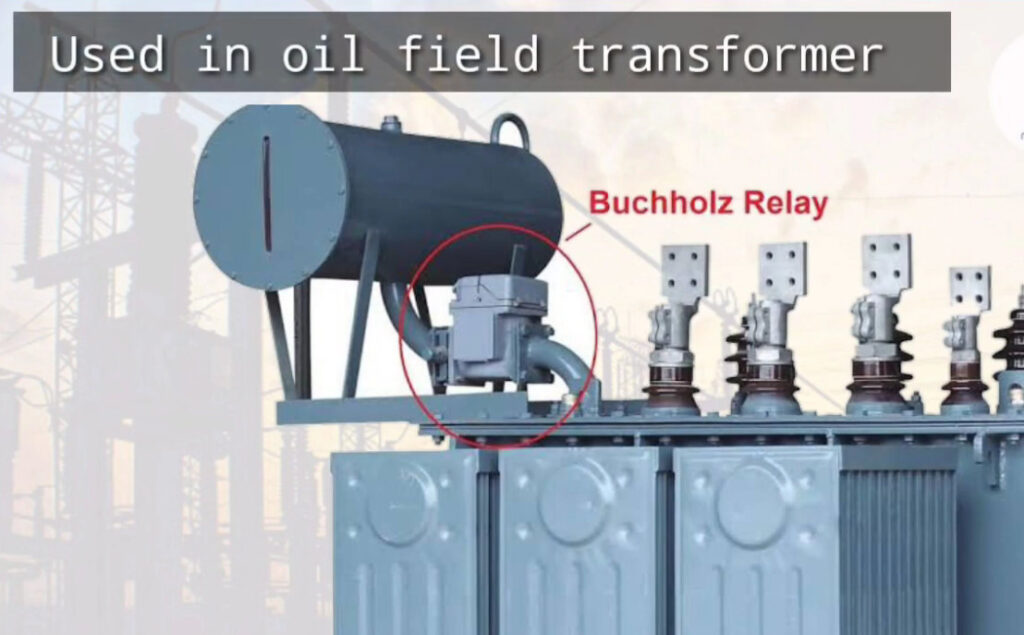

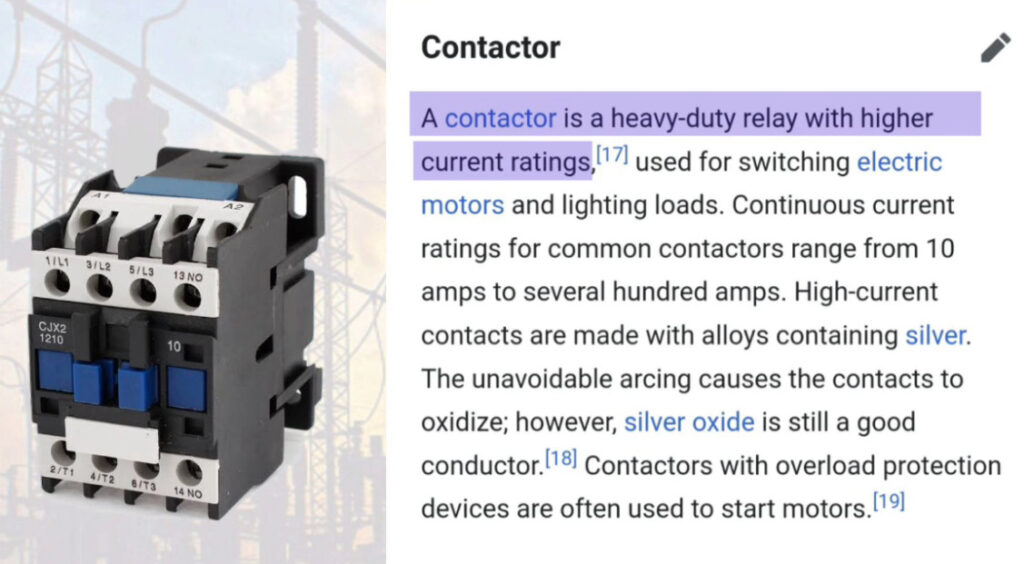

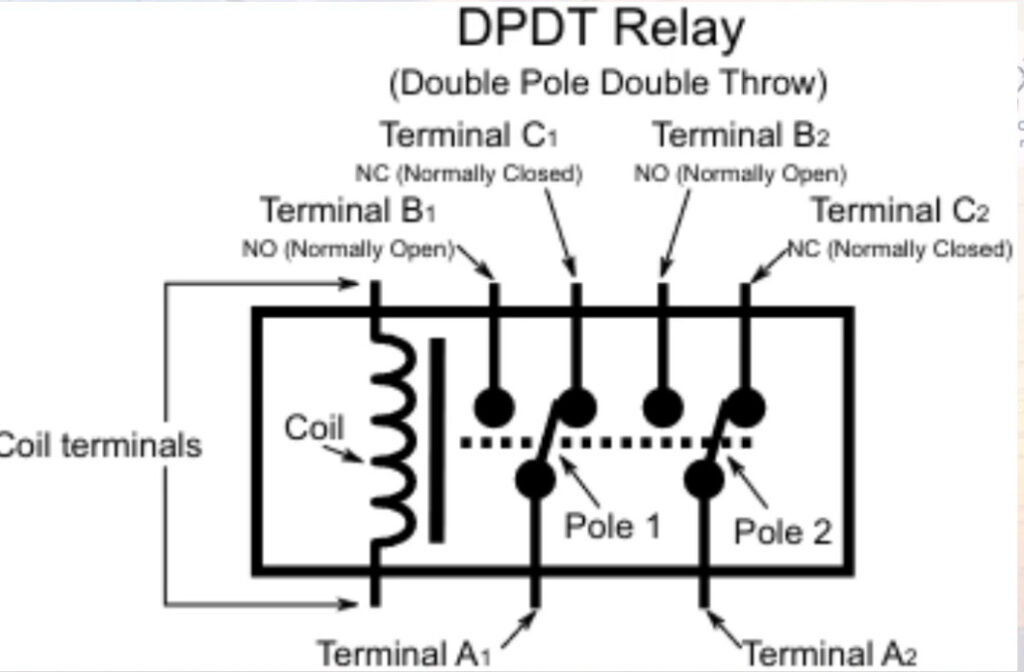

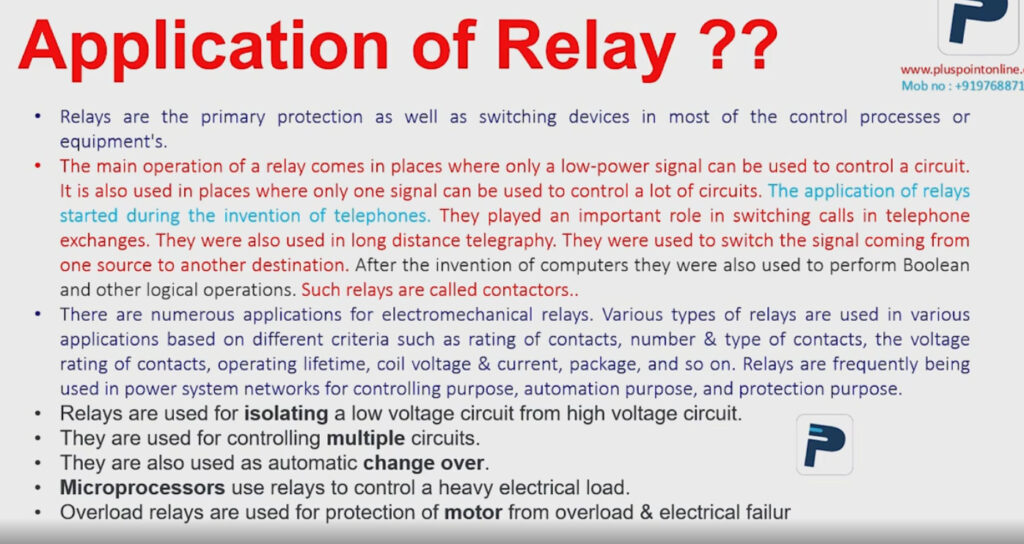

Relays come in various types, each designed for specific applications or characteristics. Here are some common types of relays:

Each type of relay has unique characteristics suited to specific tasks, from simple switching to complex automation and protection. The choice of relay depends on factors such as switching speed, current and voltage ratings, application environment, and reliability needs.