Types of Fire Extinguishers: A Complete Guide

Along with ensuring you have the right types of fire extinguisher, you will also need to make sure that you select the right sizes and weights. Read more about the current UK extinguisher regulations.

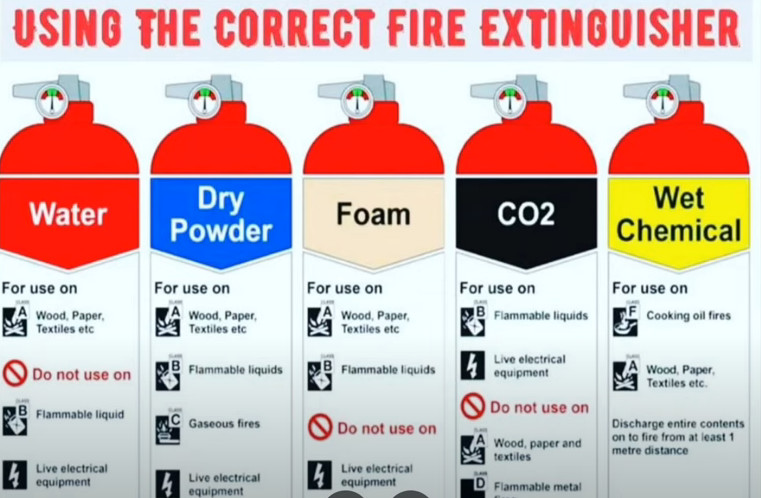

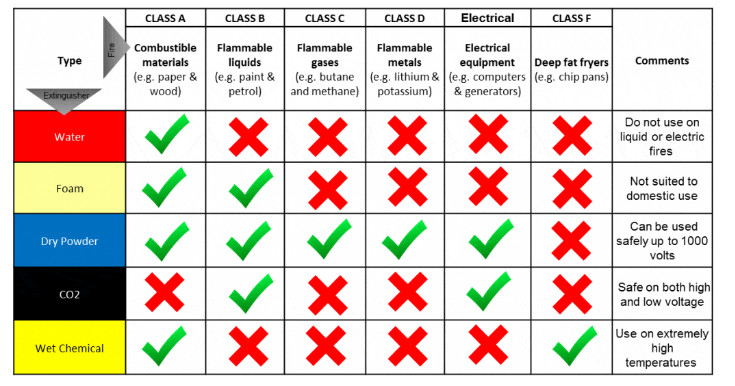

The various types of fire extinguisher put out fires started with different types of fuel – these are called ‘classes’ of fire. The fire risk from the different classes of fire in your business premises will determine which fire extinguisher types you need.

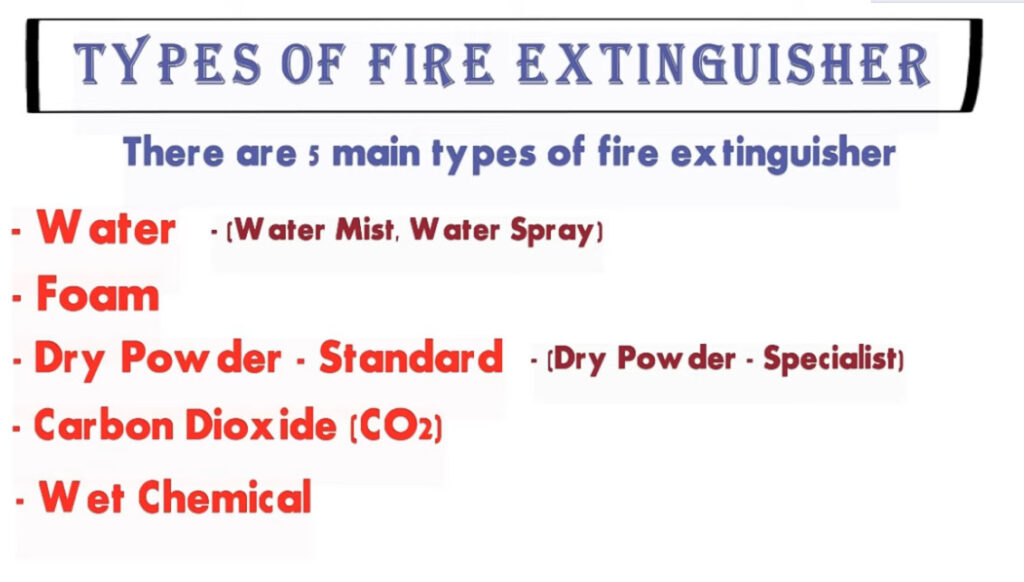

Whilst there are 5 main types of fire extinguisher, there are different versions of both the Water and Dry Powder extinguishers, meaning there are a total of 8 fire extinguisher types to choose from. The 8 types of fire extinguisher are:

– Water

– Water Mist

– Water Spray

– Foam

– Dry Powder – Standard

– Dry Powder – Specialist

– Carbon Dioxide (‘CO2’)

– Wet Chemical

There is no one extinguisher type which works on all classes of fire.

Below is a summary of the classes of fire, and a quick reference chart showing which types of extinguisher should be used on each. We then provide a detailed explanation of each type of fire extinguisher below.

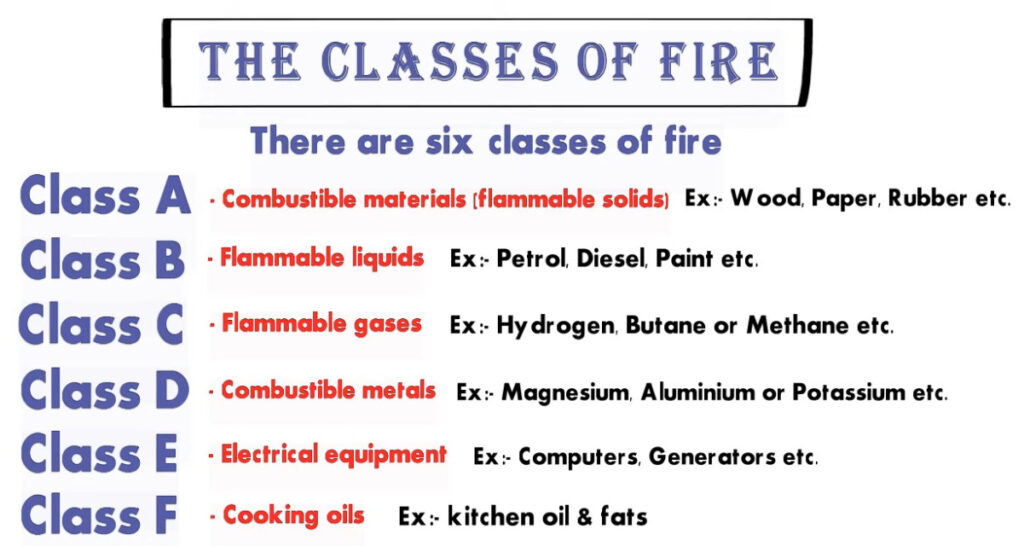

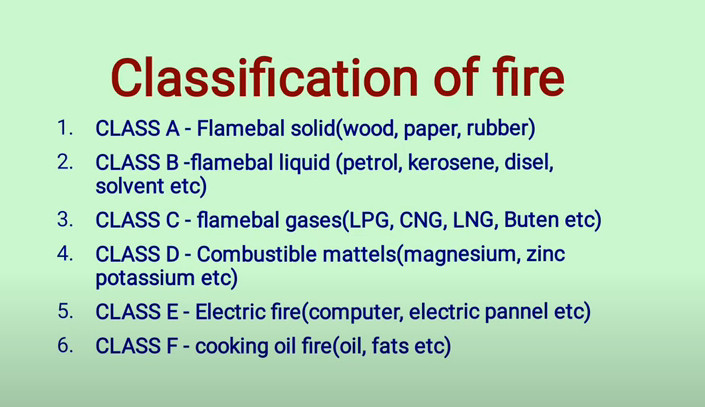

Classes of fire

There are six classes of fire: Class A, Class B, Class C, Class D, ‘Electrical’, and Class F. –

– Class A fires – combustible materials: caused by flammable solids, such as wood, paper, and fabric

– Class B fires – flammable liquids: such as petrol, turpentine or paint

– Class C fires – flammable gases: like hydrogen, butane or methane

– Class D fires – combustible metals: chemicals such as magnesium, aluminium or potassium

– Electrical fires – electrical equipment: once the electrical item is removed, the fire changes class

– Class F fires – cooking oils: typically a chip-pan fire

Which extinguisher is used for each class of fire? – quick guide

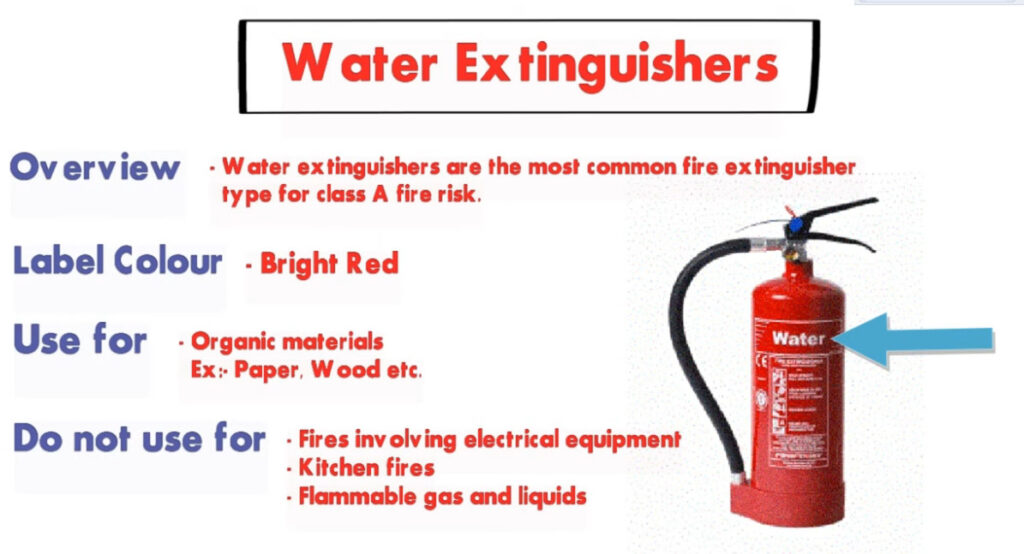

Water Extinguishers

Overview:

Water fire extinguishers are the most common extinguisher type for class A fire risk. Most premises will require either water or foam extinguishers.

Label Colour:

– Bright Red

Use for:

– Organic materials such as:

o Paper and cardboard

o Fabrics and textiles

o Wood and coal

Do not use for:

– Fires involving electrical equipment

– Kitchen fires

– Flammable gas and liquids

How water extinguishers work:

The water has a cooling effect on the fuel, causing it to burn much more slowly until the flames are eventually extinguished.

Types of premises/business who may need water extinguishers:

– Buildings constructed of wood or other organic materials

– Premises where there are organic materials to be found such as:

o Offices

o Schools

o Hospitals

o Residential properties

o Warehouses

In fact, most buildings need either water or foam extinguishers.

Where to locate water extinguishers:

– By the exits on a floor where a Class A fire risk has been identified

Water spray extinguishers – what’s the difference?:

Water spray extinguishers are equipped with a spray nozzle, rather than a jet nozzle, meaning a greater surface area can be covered more quickly and the fire put out more rapidly.

Water mist extinguishers – what’s the difference?:

Water mist extinguishers have a different type of nozzle again which releases microscopic water particles. These particles ‘suffocate’ the fire and also create a wall of mist between the fire and the person using the extinguisher, reducing the feeling of heat.

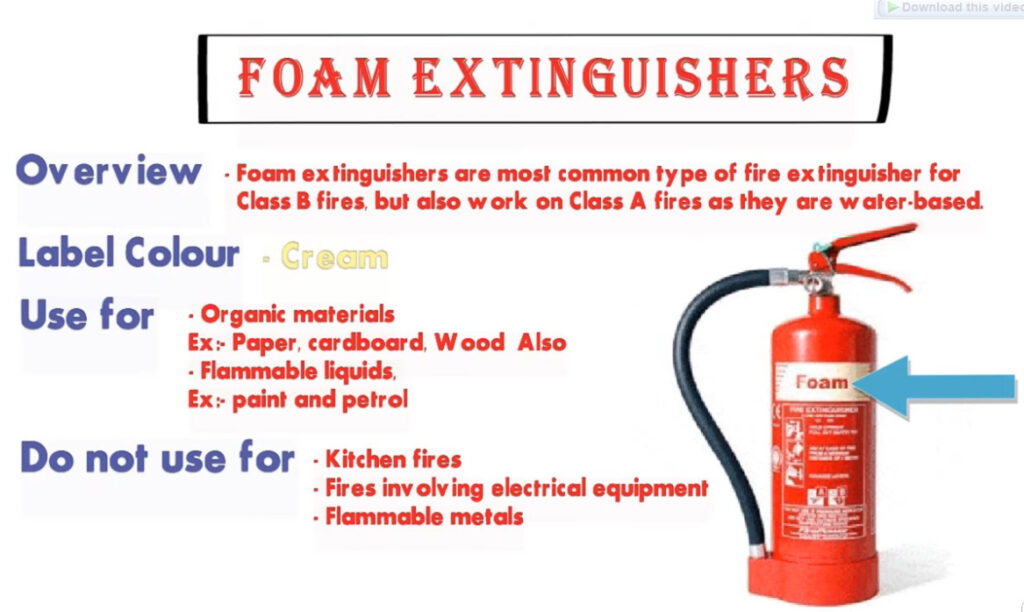

Foam Extinguishers

verview:

Foam fire extinguishers are most common type of extinguisher for Class B fires, but also work on Class A fires as they are water-based.

Label Colour:

– Cream

Use for:

– Organic materials such as:

o Paper and cardboard

o Fabrics and textiles

o Wood and coal

Plus:

– Flammable liquids, like paint and petrol

Do not use for:

– Kitchen fires

– Fires involving electrical equipment

– Flammable metals

How foam extinguishers work:

As with water extinguishers, foam extinguishers have a cooling effect on the fuel. On burning liquids, the foaming agent creates a barrier between the flame and the fuel, extinguishing the fire.

Types of premises/business who may need Foam extinguishers:

– Buildings constructed of wood or other organic materials

– Premises where there are organic materials to be found such as:

o Offices

o Schools

o Hospitals

o Residential properties

o Warehouses

– Buildings where flammable liquids are stored

In fact most buildings need either water or foam extinguishers

Where to locate foam extinguishers:

– By the exits on a floor where a Class A or Class B fire risk has been identified

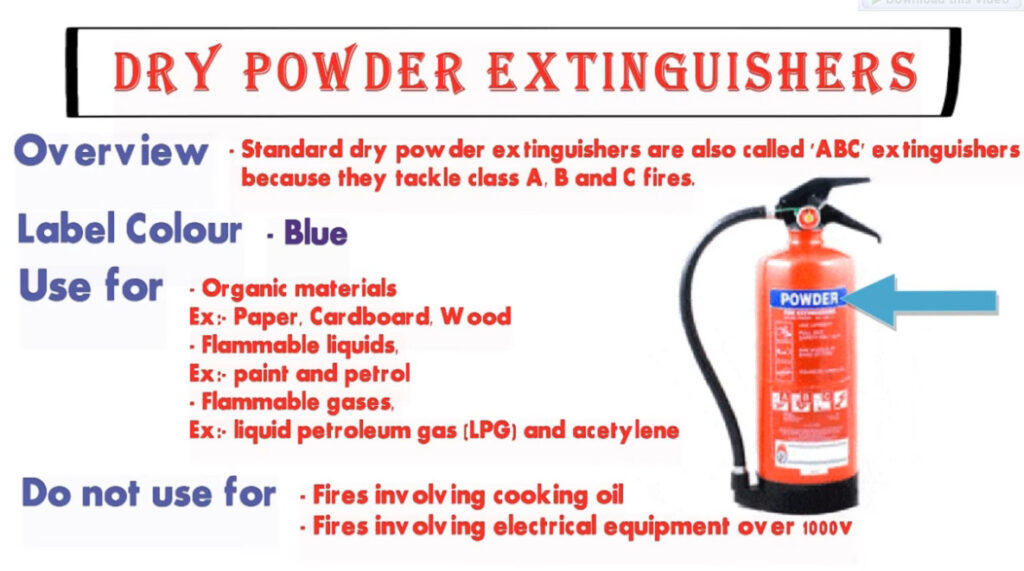

Dry Powder Extinguishers

Overview:

Standard dry powder fire extinguishers are also called ‘ABC’ extinguishers because they tackle class A, B and C fires, however, they are not recommended for use in enclosed spaces. This is because the powder can be easily inhaled, and also the residue is very difficult to clean up after. ABC powder extinguishers can also be used on some electrical fires. Specialist dry powder extinguishers are used for flammable metals.

Label Colour:

– Blue

Use for:

– Organic materials such as:

o Paper and cardboard

o Fabrics and textiles

o Wood and coal

Plus:

– Flammable liquids, like paint and petrol

Plus:

– Flammable gases, like liquid petroleum gas (LPG) and acetylene

Plus:

– Fires involving electrical equipment up to 1000v

Specialist dry powder extinguishers are only used on flammable metals, such as titanium and magnesium.

Do not use for:

– Fires involving cooking oil

– Fires involving electrical equipment over 1000v

– or in enclosed spaces, such as offices or residential properties

How dry powder extinguishers work:

Dry powder extinguishers smother fires by forming a barrier between the fuel and the source of oxygen.

Types of premises/business who may need Dry Powder extinguishers:

– Businesses using flammable gases for chemical processes

– Premises where welding and flame cutting takes place

– Garage forecourts

– Liquid petroleum gas (LPG) dispensing plants

– Premises with large, commercial boiler rooms

Where to locate Dry Powder extinguishers:

– Place dry powder extinguishers near to the source of the fire risk.

Specialist Dry Powder extinguishers – what’s the difference?:

Specialist dry powder extinguishers work in the same way as standard dry powder extinguishers but are for use with flammable metals only. There are 2 types of specialist dry powder extinguishers – ‘L2’ which only tackles lithium fires, and ‘M28’, for all other flammable metal fires.

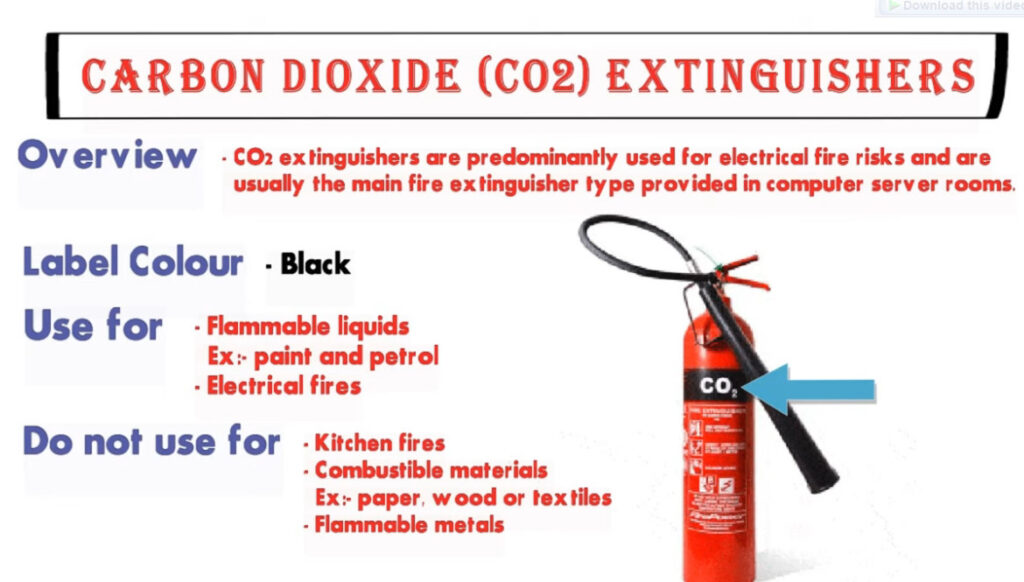

Carbon Dioxide (CO2) Extinguishers

Overview:

CO2 fire extinguishers are predominantly used for electrical fire risks and are usually the main extinguisher type provided in computer server rooms. They also put out Class B fires (flammable liquids, such as paint and petroleum).

Label Colour:

– Black

Use for:

– Flammable liquids, like paint and petrol

– Electrical fires

Do not use for:

– Kitchen fires – especially chip-pan fires

– Combustible materials like paper, wood or textiles

– Flammable metals

How CO2 extinguishers work:

CO2 extinguishers suffocate fires by displacing the oxygen the fire needs to burn.

Types of premises/business who may need CO2 extinguishers:

– Premises with electrical equipment, such as:

o Offices

o Kitchens

o Construction sites

o Server rooms

All work vehicles should also carry a smaller 2kg CO2 extinguisher.

Where to locate CO2 extinguishers:

– Place near to the source of the fire risk and/or near the fire exits.

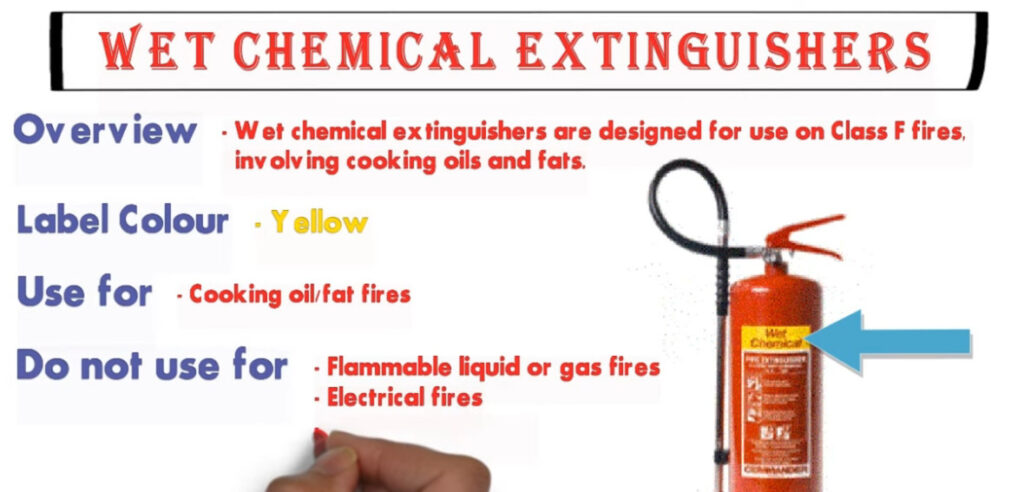

Wet Chemical Extinguishers